E-Pharma sanitary Tube-in-Tube heat exchanger was special developed for WFI point of use cooling application when flow rate is less than 1500Lph, it’s easy to be installed and operation, quickly cooling response time, no contamination risk and free maintenance.

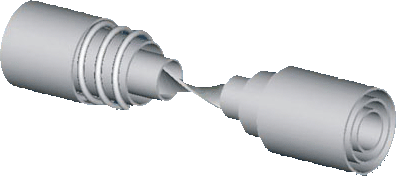

The unit is made up of three seamless tubes placed within each other. Between the services tubes there are spirals to make sure that the space is kept between the tubes and to create a turbulent flow and therewith a better heat transfer. There are no any crevices or dead spots in product channel. The three tubes are then bent together 180° to a U-bend. E-Pharma bends the three tubes with the spirals in one step which makes it no leakage risk (no welds in the turn). The product is going in the middle tube and the cooling or heating media in the inner and outer ones. A counter-current flow gives the most efficient heat transfer and also the possibility to have crossing temperature programs.

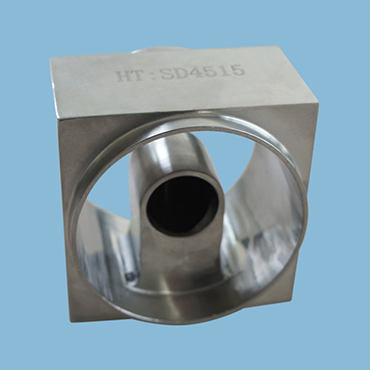

Any thermal expansion is taken up by the bend so the unit is very resistant against thermal fatigue that comes from big temperature differences in heating/cooling duties or when sterilizing with steam. The heat exchanger can be sold as a naked unit or a complete point of use cooler, the module is to prefer since it is easy to install and use directly. The module consists of the E-Pharma Tube-in-Tube, cladding, valve arrangements and a pitot tube arrangement etc. The pitot tube is especially made for E-Pharma tube in tube heat exchanger connect to main pipe system. Two standard sizes of tube in tube heat exchanger, 0~1000Lph, and 1000~1500Lph.